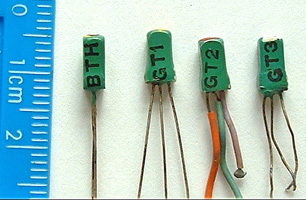

'Let’s start right at the beginning. Around 1941 BTH was involved in the development of radar, in particular the magnetron (which they started to manufacture, I was told, without really knowing how they worked !!) and the associated hardware including crystal rectifiers (or diodes as they are now called) which were mainly used as frequency converters. These crystal rectifiers were point contact silicon, capable of working at very high frequencies (3cm and 10cm band radar) and constructed in two forms : form A was a plug-in type and form B was a metal-screened plug-in type. There was also a form C which was tubular with metal end caps and wires for soldering into lower frequency applications.

In early 1950 I was a BTH apprentice and worked for six months in a small out building (building 147, I recall) which was part of their research lab. In the building was a Mr Evans (my boss), a lady who did a lot of routine test work and myself, all working on the development of the rectifiers. In overall charge of the department was a Mr T H Kinman. Also in our building was a guy experimenting with transistors. Apart from himself, he had, in a separate room, three girls actually making transistors. They were point contact silicon and they were in effect simply diodes with an extra contact. (There is a question here - I believe that the transistors were germanium, not silicon. See Harry Metcalfe's statement that Kinman was an expert on refining germanium. - Andrew W.)

Making them was slow and tedious, the point contacts being adjusted manually with the aid of what looked like special microscopes. I myself had no involvement with this side of the work other than the fact that we shared the same work place so I got to know what went on.

The problem was that having made the transistors, nobody seemed to know quite what to do with them. This was because the transistors had a low input impedance and a high output impedance which is exactly opposite to thermionic valves. This meant that if used in a radio or television instead of valves, no existing associated components or circuits were compatible. Eventually they came to the conclusion that because of this impedance problem, transistors had no commercial future and the team was disbanded, I think, in late 1950.

Here is a photo of the people involved in early Transistor work at BTH.It was taken outside the lean-to shack attached to the rather larger building where I worked on development testing of centimeter-wave diodes. The date would be around May 1950.

Here is a photo of the people involved in early Transistor work at BTH.It was taken outside the lean-to shack attached to the rather larger building where I worked on development testing of centimeter-wave diodes. The date would be around May 1950.

From left to right the people are -

- J H Evans in charge of 3 and 10cm diode development testing. He was my boss.

- One of the ladies who worked in the shack making point contact transistors for development.

- Cynthia - J H Evans' test assistant.

- As (2) above.

- Me - a 20 year old apprentice, working for J H Evans chiefly involved in making his test gear.

- The guy in charge of (2) and (4) and whose work was stopped later that year.

Work on diodes continued and by 1951 they were making significant quantities of glass encapsulated wire ended ones, on a production line basis in Frank Whittle’s old factory in Lutterworth. As far as I can remember, these were germanium and still mostly point contact. Eventually production was transferred to their Lincoln factory.

It was, I believe, several years before transistor manufacture was revived by BTH. I do know that around 1961 a friend of mine was involved on research and small scale production of germanium junction types in a new building attached to the Rugby research lab. Where quantity production was based, I do not know. My friend, who in 1966 transferred from Rugby to the Lincoln factory, says that to the best of his knowledge only diodes were made in Lincoln'.

Richard Groom, January 2008.

Obviously this is a historically important account, so if any reader knows anything about this, please - Andrew Wylie.